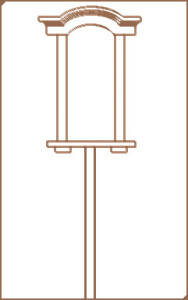

Goal: Create a Distinctive Law firm sign that optimized the signs visability, allowing for additional tenants and partners, while taking a relative small footprint, but delivering a large canvas.

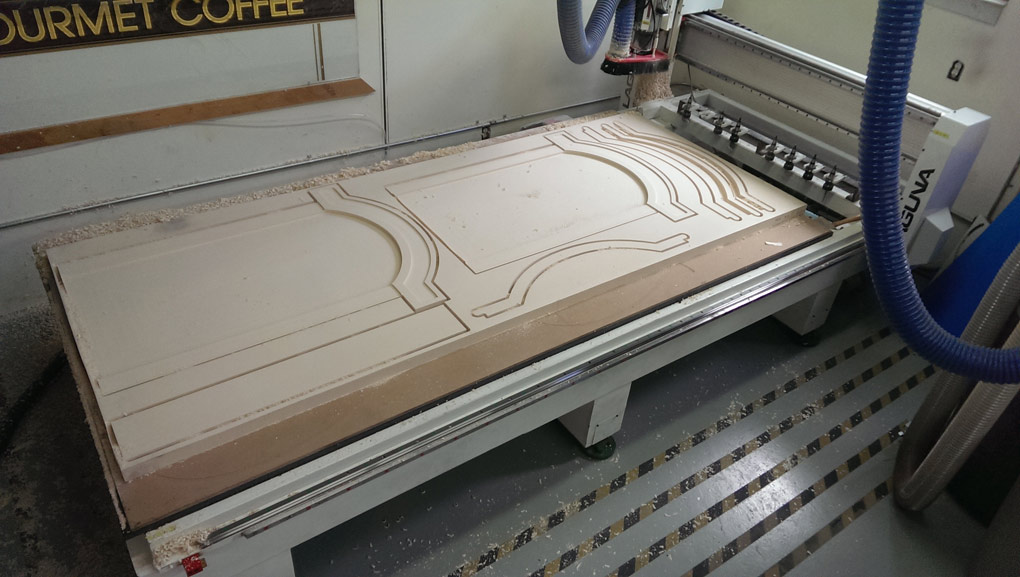

A new law firm sign gave us a chance to design and build a challenging new computer sign carving project. After creating a detailed design and getting final approval from our client, we prepped the file and material to run through our Laguna SmartShop II. Cut from one 4’x10′ panel, we maximized the design and material. These pieces were assembled in to one 3D sign. I think we used every bit of the panel on this one. The material is our favorite, HDU – High Density Urethane, incredibly stable and ideal for computer sign carving on a CNC.

A new law firm sign gave us a chance to design and build a challenging new computer sign carving project. After creating a detailed design and getting final approval from our client, we prepped the file and material to run through our Laguna SmartShop II. Cut from one 4’x10′ panel, we maximized the design and material. These pieces were assembled in to one 3D sign. I think we used every bit of the panel on this one. The material is our favorite, HDU – High Density Urethane, incredibly stable and ideal for computer sign carving on a CNC.

Once the sheet is cut we can start assembly. The roof of the sign was made from four identical pieces, glued and sanded.

Before the sign is glued up, the parts are dry assembled to assure proper fit. Assembly and final sanding is streamlined with the precise cutting done by SmartShop II. Designs that would take weeks to execute can be milled quickly and deliver stunning results.

Steel interior structure for CNC sign

A lollipop design required an interior steel structure necessary to insure that the sign will withstand a wind load. In this case we have milled a grove 1/2 depth to receive 1.5″x1.5″ perforated steel tubing into both sign halves. These steel tubes are welded to a 1/4″ thick steel plate that is welded to the sign post.

Sign glued up and clamped

Exterior urethane glue is applied to both sign halves and the sign is clamped together. The next day the sign is ready for painting.

Final Sign installed in brick walkway